Do you know what’s even more complicated than cooking up delicious food in a food truck or trailer? Dealing with all the plumbing and water system shenanigans! That’s right, folks, the world of mobile food is not just about whipping up tasty treats; it’s about navigating a maze of pipes and fixtures. So, grab your wrench and let’s dive into the wild world of plumbing in food trucks and trailers.

Planning the Plumbing System for Your Food Truck/Trailer

Just like a chef maps out a recipe before cooking up a storm, you need to plan your plumbing system ahead of time. Think about the type of food you’ll be serving and the equipment you’ll be using. Consider things like three compartment sinks, handwashing stations, and water heater (because, water heater and hand sinks are mandatory in every food truck or food trailer in all states in the U.S).

When it comes to designing the plumbing system for your food truck or trailer, there are several factors to take into account. One of the most important considerations is if you have a commercial/Commissary kitchen – the vast majority of food trucks and food trailers operate out of a Commissary kitchen. If you do you can do your prep there, do your mopping and cleanup there and wash dishes there. This negates the need for the Prep Sink, Three compartment sink and a mop sink.

Veteran restaurateurs understand these different terms but let’s dig into them a little. These are the four types of sinks that you would see in a food truck:

Hand wash sink:

A hand wash sink as the name suggests is a sink made out of stainless steel for the express purpose of washing and sanitizing one’s hands. Every single health department or county out there requires that this be present in a food truck or food trailer.

To conditions need to be met for this piece of equipment to be acceptable:

- The sink needs to be plumbed with both hot (scalding hot) and cold water.

- The sink itself needs to be NSF approved.

- Some jurisdictions require that the sink has splash guards on the side

Mop Sink:

Typically these are floor mounted, although other options are plenty. These are used while you mop the truck or trailer down. In most jurisdictions this isn’t a requirement if you have a commissary to work out of, but if you have the space for it, why not?

Three compartment or three hole Sink:

These are used to wash, rinse and sanitize dishes and spoons used in cooking and serving. Even if you are washing dishes in the commissary kitchen many jurisdictions require that you have these in the truck or trailer regardless.

Three compartment sinks are required to be NSF approved and have both hot/cold water as well.

Some counties have additional rules related to these – for example the largest cooking utensil should fit inside the sink. Some require that the sinks should get filled within 20seconds, this will influence the pump selection.

Others require drain-boards on the side of the sink to drain the water off, this can be a bit of a pain to accommodate in smaller foot prints of food trucks and food trailers.

Prep Sink:

Prep sinks are used to wash vegetables or other ingredients for cooking, these tend to be one large compartment, quite deep as well.

Photo courtesy: KaTom

Some prep sinks come with drain-boards on one or both sides to help drain the water off, but these are not mandated by any county we have worked with, that being said it is a neat feature to have.

Next up are the tanks, thanks to the RV industry we have access to a large number and types of tanks available to us, no matter the size and complexity of the project there is a type of tank that will fit your need, and if not there are molders out there who would custom make tanks for you, although those tend to be pricy.

Here are the two major types of tanks that are fitted in a Food truck or trailer:

Fresh water tank:

These hold not necessarily but more often non-potable water for cooking and cleaning purposes in a food truck or trailer. Typically made using blow molding, injection molding or more commonly thermos forming the tanks can either be mounted under the sinks(inside the custom foodtruck/foodtrailer) or underneath it, although that’s more common in step van to Food truck conversions or bus to Foodbus conversions as these tend to have a lot of space under their bodies.

In some cases customers ask us to add more than one fresh water tank – sometimes for special machinery like Espresso machines or in the picture below for a special washing machine that washes nixtamalized corn in a mobile Tortilla Factory:

Grey water tank:

As the name suggests the grey water tanks hold the water that runs off from the sinks, most jurisdictions(and good sense) require these to be at least 15% bigger than the fresh water tank, when we select these are typically 50gallon when the fresh water tank is 40gallon.

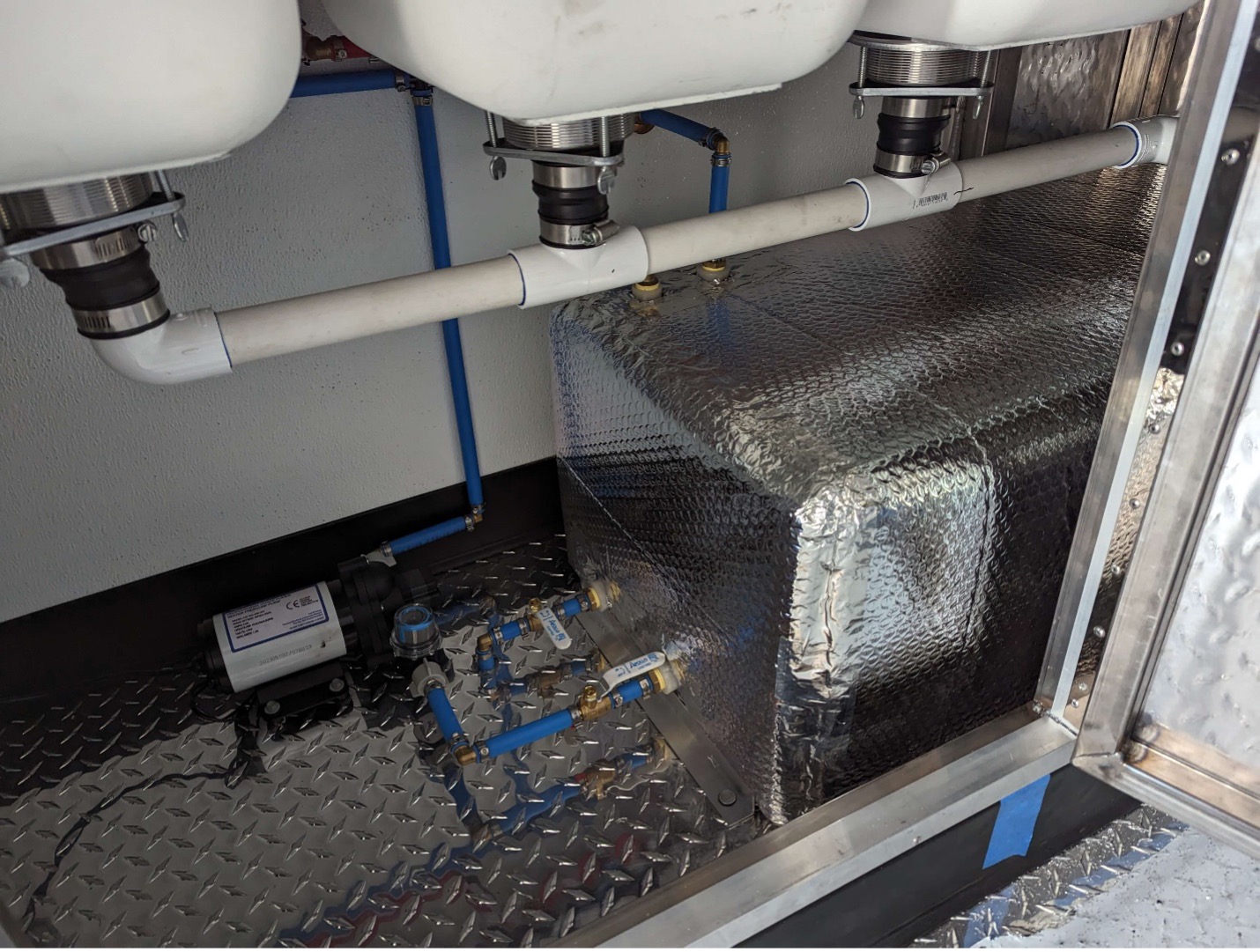

Whatever the size you choose, it is imperative that they be securely mounted to the truck or trailer and if used in northern climates, be insulated.

Tubing/Pipes:

Vast majority of the plumbing in a mobile kitchen is done using PEX tubing, which works quite well and is easy to install and repair. These are also flexible and don’t tear themselves apart when you brake really hard or have to accelerate to pass someone.

Picture courtesy: Mile High Custom Food Trucks

Pump:

This ought to be the part that fails most often in a Food truck, unfortunately. Which is surprising considering it doesn’t have many moving parts. We think it’s because pumps never really completely drain and the freeze/thaw cycle is what gets them. Needless to say we keep a few spares in the shop all the time.

Essential Considerations for Choosing Plumbing and Water Systems

Choosing the right plumbing and water systems can be a daunting task. Here are a few considerations to keep in mind:

- Water capacity: Make sure your truck or trailer has enough water storage to meet your needs. Nobody wants to run dry in the middle of a lunch rush!

- Quality components: Invest in high-quality, durable fixtures and pipes. You don’t want leaks and bursts cramping your style.

- Easy access: Plan your plumbing layout in a way that allows for easy maintenance and repairs. Trust us, you’ll thank yourself later.

- Regulations: Don’t forget to check local health department regulations regarding plumbing requirements. The last thing you want is a spicy visit from the health inspector

Ways to Avoid Water System Issues in a Food Truck/Trailer:

Here are some tips to keep your water flowing smoothly:

- Regular inspections: Inspect your plumbing system regularly. Catching problems early can save you from a world of trouble later on.

- Proper disposal: Don’t use your sinks as trash cans. Dispose of leftover food scraps properly to prevent clogs and backups.

- Insulation in winter: Protect your water system from freezing temperatures with proper insulation. Your customers will thank you for that hot cup of cocoa!

- Keep it clean: Regularly clean and sanitize your fixtures to keep things sparkling and germ-free. Your food and your customers will appreciate the extra hygiene.

Approaches to Installing Plumbing in a Food Truck/Trailer

When it comes to installing plumbing in your food truck or trailer, there are a few approaches you can take:

- DIY: If you’re a plumbing enthusiast and love getting your hands dirty (not literally, we hope), you can tackle the installation yourself. Just make sure to do your research and follow all safety guidelines.

- Hire a professional: If you’re not confident in your DIY skills or prefer to leave it to the experts, hiring a professional plumber is always a smart choice. They’ll ensure everything is installed correctly and up to code.

- Calling all-in-one services: Some companies specialize in food truck and trailer conversions, offering all-in-one services that include plumbing installation. It’s like ordering a combo meal – convenient and efficient!

Choose the approach that suits your skills and comfort level. After all, installing plumbing should be a rewarding experience, not a soggy mess!

Best Practices for Maintaining Plumbing and Water System in a Food Truck/Trailer:

Maintenance is the key to a happy and hassle-free plumbing system. Here are some best practices to ensure your pipes stay in tip-top shape:

- Regular cleaning: Keep those sinks shining with regular cleaning and sanitization. Clean fixtures are happy fixtures!

- Monitor for leaks: Stay vigilant and fix any leaks promptly. Water conservation saves both the planet and your wallet.

- Don’t ignore the drains: Clogged drains can be a recipe for disaster. Use drain covers and clear out any lurking culinary surprises.

- Winterize: If you live in a chilly climate, winterize your water system to prevent frozen pipes. After all, no one wants ice sculptures in their food truck!

By following these best practices, you’ll keep those plumbing woes at bay and ensure smooth sailing in your food truck or trailer.

Food truck plumbing system that can be used in all seasons:

Let’s talk about the holy grail of food truck plumbing: a system that can withstand all seasons! You don’t want your business going on a hiatus just because of a little snow or heatwave. Here are some tips for a year-round plumbing system:

Insulation: Insulate your tanks to prevent freezing in winter and bursting in summer. It’s like wrapping your plumbing system in a cozy sweater!

Picture courtesy: Mile High Custom Food Trucks

Flexible water tanks: Invest in flexible water tanks that can withstand extreme temperatures without cracking. They’ll be your secret weapon for conquering the seasons.

Maintenance, maintenance, maintenance: Regularly inspect and maintain your plumbing system to catch any issues before they become season-ending problems. With these tips, you’ll have a plumbing system that can take on snow, rain, sleet, or sunshine.

Wrapping Up

When it comes to plumbing and water systems in food trucks and trailers, it’s a wild ride. But with proper planning, regular maintenance you can run a profitable food truck business for a long, long time.

In the confined spaces of smaller Food trailers it might be wise to choose a V-nose trailer to exploit the bonus space in the front to accommodate the sinks, like in this trailer we shipped a while back:

We have a customer for whom we built a trailer sixteen years ago, he has since bought three more from us over the years, and the first trailer still runs as good as the last one.

Here is a video tour of plumbing system in a food truck we recently delivered: